OUR CASE HISTORIES

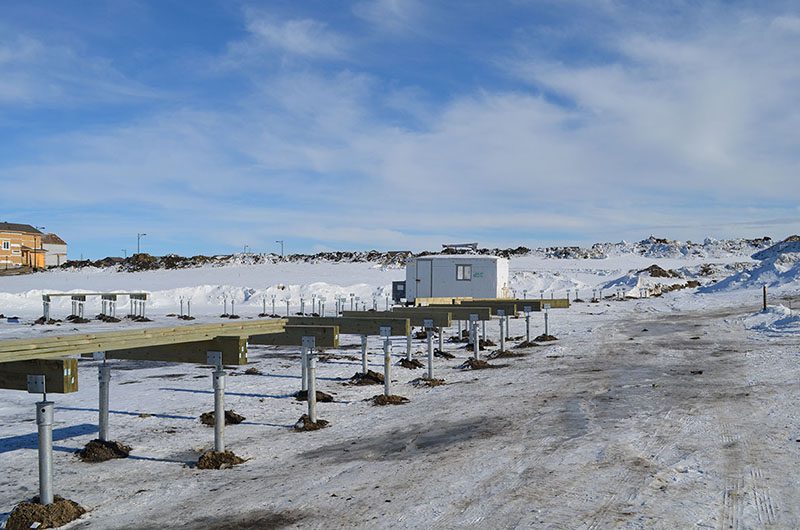

LAND TEC – BOARDWALK PILES

This man-made storm water retention lake required viewing platforms and boardwalk. Single length galvanized piles were designed to handle both downward loads and uplift loads. Originally we tendered this project to be done after the lake was pumped down during the summer months. Due to scheduling issues on the part of the developer, the project was not given a green light until late fall. This meant that we would have to do the project during the winter months if we wanted the job. We would need to come up with an approach for installing these piles during the coldest part of the winter.

PROJECT GOALS

- Install 136 piles with brackets to support beam work for boardwalk

- Successfully installed all piles level and plumb

- Install piles within an eight day period

OUR APPROACH

- We elected to deal with the ice on the lake and frost by pre-drilling a 16” diameter hole using a frost – rock auger on a T300 Bobcat with snow tracks

- In order to install a 20 foot long single piece screw pile we had to modify our drive head attachment to handle the required height.

- We used a 20,000 foot pound drive head on a Kubotta SVL90 Skid Steer with snow tracks for the installation.

- Pile was installed to within 4 feet of anticipated end elevation then left

- Once all piles were installed to 4 feet of end height we shortened our drive attachment to decrease sway and install the pile to depth with more control in order to get it plumb.

- All piles were installed to within .5 of an inch to plumb.

- Galvanized adjustable brackets were bolted on and adjusted for heights shot in with a laser level.

- Successful pile installation made boardwalk installation easy for follow up crew building boardwalk.

- More pictures to follow this summer after landscaping on lake is complete